Impromptu Lock Picks

by L. Gallion

This article assumes you are familiar with lockpicking and lockpicking tools. If you are completely new to the subject, I suggest you Google/Yandex for the MIT Guide to Lockpicking (PDF) and read it before continuing.

To pick a lock, you need two things: a pick and a tension wrench.

The pick is used to press on or rake across the pins inside a lock while the tension wrench applies a turning force to the lock's cylinder. The trouble is it isn't always practical (or even legal, depending on local ordinances) to carry professional lockpicking tools. Fortunately, most homes and offices come stocked with all of the materials necessary to make your own basic tools.

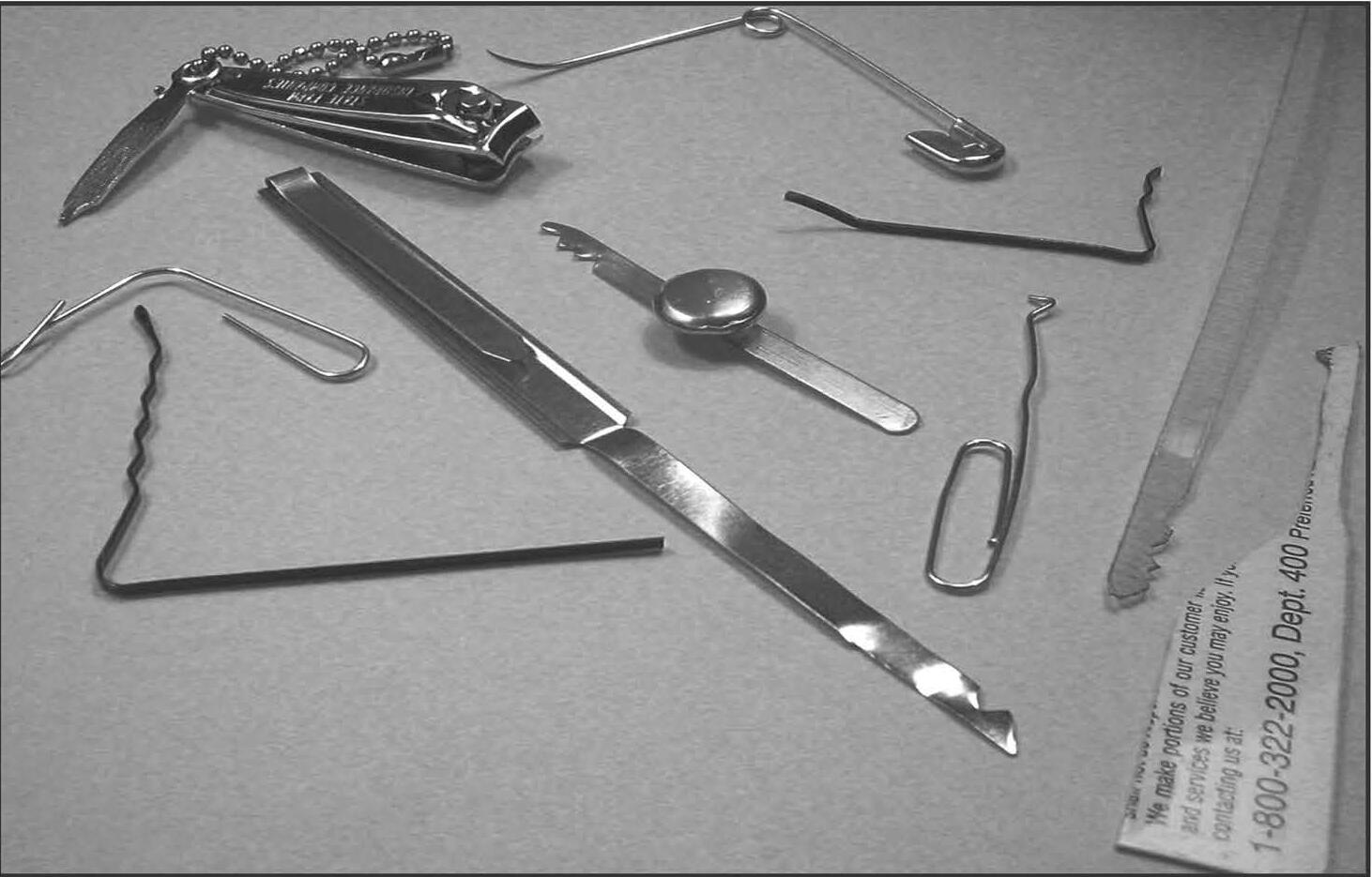

For example, here are some items I rounded up in just a few minutes:

- Fingernail clippers. The kind with a built-in nail file and a little hole at one end.

- A couple of bobby pins.

- An old credit card, or any plastic card of similar thickness.

- A couple of small paper clips.

- A large safety pin.

- A "Prong Fastener" (ACCO #70022, used to hold large printouts together)

- A good pair of steel scissors.

- A plastic cable tie, used to secure cables and wires together.

- A round-head brass fastener.

Using just these items and a little imagination, we can create several different lockpicking tools.

Let's get started with the most limited of our resources, the paper clips.

Professional picks and wrenches are often made from hardened, flat spring steel, while paper clips are round, soft, and bendable. This means that paper clip picks are only useful against locks with weak pin springs and paper clip wrenches only work with easily turned cylinders.

To make a paper clip pick, straighten out one end of the paper clip (leave the other end curled as a handle) and then bend the very end of the straight section into a small, sharp "hill" sticking up (this is the classic half-diamond pick shape).

The easiest way to do this is to clamp (don't press too hard) about a quarter-inch of the paper clip in the jaws of the fingernail clippers and use the clippers to bend the paper clip. Do this again about one-eighth of an inch in from the end to finish forming the hill shape.

The end of the paper clip should look roughly like this:

______/\ |

While too soft to work as an actual pin pick, a paper clip can be used to rake simple locks, like the disk tumblers you will find in most Steelcase and HON filing cabinets, desks and overhead bins.

To make a paper clip tension wrench, unfold the paper clip as before (leaving one curled end as a handle) and then bend about a half-inch of the straightened portion back onto itself. You will want to make the actual bend as small as possible, so use a hard object to press on the bend and "close" it as much as you can (the scissor handles work well here).

Finally, bend the "handle" so the paper clip now has an "L" shape.

The bend at the end of the paper clip will usually fit into the bottom of the keyhole of most medium sized locks. However, a paper clip tension wrench is very weak and I have only used it successfully on smooth working deadbolts.

Now let's move on to a much better tool: the safety pin pick.

Steven Hampton, author of Secrets of Lockpicking, says he got started using just a safety pin pick and a bent screwdriver as a tension wrench. Now you too can make just such a pick in seconds.

First, carefully open up the safety pin and use the clipper's nail file to dull the point (so you won't poke yourself).

Next, insert the pin through the hole at the rear of the fingernail clippers. The pin should just barely be sticking out of the far side of the hole.

Then, by rotating the entire clippers up or down, you can pinch and bend the portion of the pin sticking through the hole.

Stop bending once the pin has a nice, gentle curve of about 45 degrees.

Finally, open the safety pin up a little wider so it stays in a permanent "L" shape.

Being strong and made of flexible steel, your new-and-improved safety pin can be used as a hook pick on a variety locks. I have successfully used it to pick five disk tumblers, four pin padlocks, and six pin deadbolts.

Next, let's tackle another strong performer, the bobby pin.

Bobby pins can be made into a good hook pick or a small tension wrench very quickly.

First, remove the little plastic tips that come on most bobby pins and spread it apart so it forms an "L" shape.

Next, insert the straight leg (not the wavy one) of the bobby pin through the hole in the fingernail clippers so that about a quarter-inch sticks out on the other side. The tricky part of the bobby pin pick is that we want to put a bend along the thin edge (not the flat sides).

To do this, tightly pinch the flat sides of the bobby pin about a half-inch back from the fingernail clipper's hole.

Then move the fingernail clipper up or down to carefully bend the bobby pin. If it starts to twist, stop and carefully straighten the twist out and then continue bending again.

Stop bending the bobby pin when you have about a 45-degree angle. You have the proper shape when you lay your metal "L" down flat on a table and the end of one of the legs sticks up.

The bobby pin tension wrench is a lot simpler. Just open up the bobby pin and spread it apart until it permanently forms an "L" shape. Although a great tension wrench, the width of the bobby pin is often too small to be used on a lot of locks.

If the bobby pin wrench is too small, try using the nail file of your fingernail clippers. Just extend the nail file out to a 90-degree angle. The nail file tip will fit into the keyhole of some medium sized locks and the body of the clippers acts as the handle.

Credit card picks are easy to make but are only strong enough for one or two picking sessions.

First, cut the credit card into about half inch strips.

Next, use a straightened paper clip to measure the depth of the lock (push it in until you hit the back wall). Using this depth, trim down one end of the credit card strip so it is small enough to enter the top of the keyway.

As you trim the end of the card down, shape the tip in either a half-diamond or half round pick style (see the MIT Guide if you are not familiar with these shapes).

Don't forget, credit card plastic is relatively soft, so try to use your fingers to support the thin shaft as you move it around within the lock.

Our final group of impromptu lock picking tools is a set of rakes.

Rakes are pulled back and forth and up and down against the pins of a lock in the hopes of opening it. While raking won't have much of an effect against most high security locks, it works very well against desks, filing cabinets, and cheap padlocks.

Our rakes will be made out of the round-head brass fastener, prong fastener, and the cable tie.

Start by straightening out one of the thin metal legs on the brass and prong fasteners. Then use your scissors to carefully cut a series of "V" shaped notches or smooth "hills" at the end of each object (just on one side).

Make certain the end is either pointed or sloped so that it can enter the keyway easily. You may also need to trim down the flat bottom portion of the rake to get it to fit into the lock.

Of these three rakes, I have gotten the best results with the cable tie.

It's tough, flexible nylon construction allows it to move smoothly in and out of most locks. However, don't think that any of these makeshift tools are going to easily crack that high-security Medeco in your office.

Advanced lockpicking takes a combination of skill, practice, luck, and the proper tools. But the next time you lock your boss's big presentation in a filing cabinet and lose the key, don't panic! Just use your lockpicking ability and a few office supplies.